Automatic Analytical Instruments for On-site / Off-site

Compact Analyzer / MarkⅡ

- For replacing manual analysis at labs either on-site or off-site.

- For limited space.

| Installation | Recommend within 10m form tank if installed on-site |

|---|---|

| Sampling capacity | 0.02ml – 10ml |

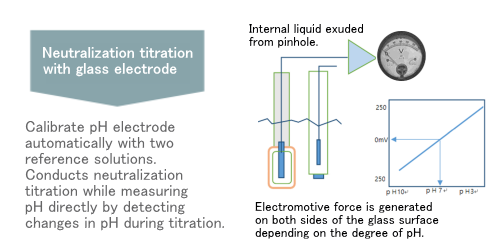

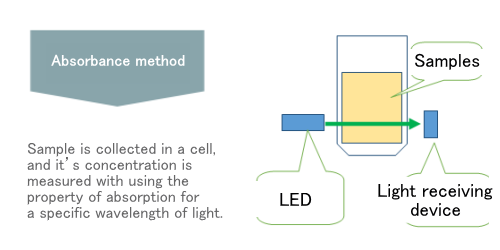

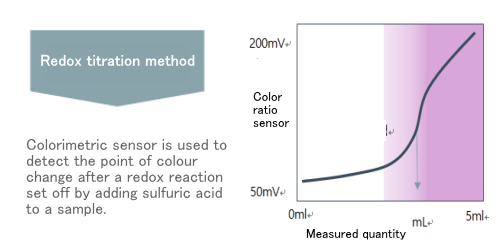

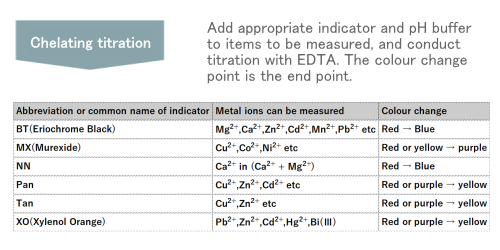

| Analysis items | Depend on manual analysis methods such as Neutralisation titration, Potentiometry, Colourimetry, absorbance, and chelating titration. |

| Operating cycles | Sampling – Analise – Calculate supply amount – Output signal for replenish |

| Analysis time | 15 – 30 min. |

| SPC (Statistical Process Control) | Able to manage/edit Excel data and trend graphs |

| Languages | Korean, English, Chinese, Japanese |

| Printing method | Thermal printer |

| Communications ports | RS485 |

| Analysis accuracy | +/- 2% – 4% |

| Dimensions | W 300 x D 200 x H 250 (mm) |

| Weight | 5.5kg |

| Power supply | AC110V/220V |

| Maintenance | Annual service is recommended (service interval may vary by operation frequency). |

ATCS (All round Titration and Control System)

- Can be installed next to a tank that needs to be controlled and monitor its trends onsite.

- Able to analyse up to four tanks.

| Installation | Recommend within 20m form tank (may vary by fluid type) |

|---|---|

| Sampling capacity | 0.02ml – 10ml |

| Analysis items | Depend on manual analysis methods such as Neutralisation titration, Potentiometry, Colourimetry, absorbance, and chelating titration. |

| Operating cycles | Sampling – Analise – Calculate supply amount – Output signal for replenish |

| Analysis time | 15 – 30 min. |

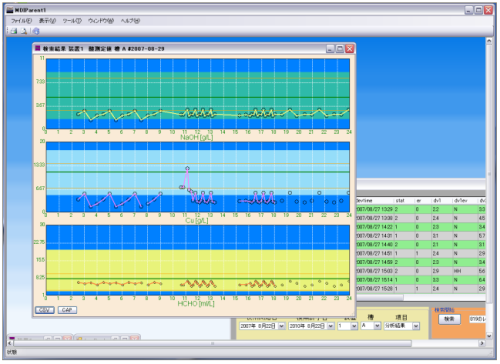

| SPC (Statistical Process Control) | Able to manage/edit Excel data and trend graphs |

| Languages | Korean, English, Chinese, Japanese |

| Printing method | Thermal printer |

| Communications ports | RS485 |

| Analysis accuracy | +/- 2% – 4% |

| Dimensions | W 380 x D 370 x H 586 (mm) |

| Rack for reagents | W 380 x D 370 x H 1000 (mm) |

| Weight | 25kg |

| Power supply | AC110V (Converter to 220V can be installed) |

| Maintenance | Annual service is recommended (service interval may vary by operation frequency). |

Expected benefits from our automatic analytical instruments.

Cost Saving

- Necessary sampling amount is less than manual analysis, and thus less titrant is needed.

- Contributes to reduce labour costs for conducting manual analysis.

- By letting our instruments analyse chemicals automatically, you can allocate your work force for such as Kaizen activities and increasing production efficiency. This enables you to increase the effectiveness of other production processes.

Quality

- High analytical accuracy (within +/- 3%).

- Real-time chemical management to prevent defective products from occurring.

- Increasing production efficiency.

Analysis mechanism

Monitoring trends (data transmission)

It is a given that our instruments can analyse and refill our customers’ chemicals.The important thing is that our customers can instantly understand the current status of production process.

- Data of up to four tanks can be displayed by installing a specialised software.

- Synchronise a control range of process to the PC and check the current status at any time by connecting our instrument to a PC (This improves awareness of your work force and plays an important role in appealing your quality control capability to your customers.)

Examples

| Examples | Analysis items |

|---|---|

| Developer’s solution (DRY FILM) | Caustic Soda / RD dissolved amount / PH |

| Electroless Copper Plating | Caustic Soda / Copper / Formalin |

| Electrolytic Copper Plating | Sulfuric Acid / Copper / Chlorine |

| Black Oxide | Caustic Soda / Hydrogen Chloride |

| Soft Etching | Sulfuric Acid / Hydrogen Peroxide / Copper |

| Electroless Nickel Plating | Nickel / pH |

| Electrolytic Nickel Plating | Ni Sulfamate / Boric Acid / Ni Chloride / pH |

| Acid Zinc Plating | Ammonium Chloride / Zinc / pH |

| Palladium Plating | Palladium / pH |

| Organic Acid Tin Plating | Tin / Organic Acid |

| Silver Cyanide Plating | Silver / pH / Cyanide |

| Cyanide Gold Plating | Gold / pH / Cyanide |

| Examples | Analysis items |

| Chrome plating | Trivalent Chromium / Acidity |

| Chemical Film Treatment | Trivalent Chromium / Zinc |

| Anodized Aluminium Plating | Free concentration / Total concentration / Dissolved Aluminium |

| Alkaline zinc plating | Caustic Soda / Carbonated root / Zinc |

| Reduction bath | pH/DMAB |

| Blackening treatment | Caustic Soda / Chlorine |

| Pickling | pH / Acidic components |

| Pickling (iron) | Acidic component / Bivalent iron |

| Chemical treatment solution | Total acid / Free acid / Accelerator |

| Zirconium (Zr) coating | Zr / pH |

| Alkali degreasing | Caustic Soda / pH |

| Surface conditioning solution | pH / TC |